Darby, PA

Time Frame: September 2017 - September 2018

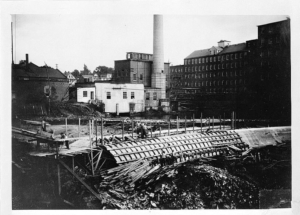

Enviro-Air was contracted to remediate a former MGP site, located on both sides of Darby Creek in Darby, PA. Fifteen thousand (15,000) tons of MGP impacted soil were excavated and disposed of offsite at a treatment/disposal facility. The excavation along the creek involved the following:

- Installation of 6,250 square feet of soldier beams and lagging to allow for the excavation of MGP-impacted soils to a depth of 23 feet below ground surface. In conjunction with the lagging, 40 tiebacks were installed.

- Installation of a well point dewatering system, which ran 24 hours per day, seven days per week.

- Installation and operation of a water treatment plant consisting of activated carbon, bag filters, a weir tank and an 18,000-gallon frac tank.

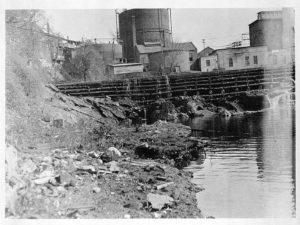

In addition to the 15,000 tons of MGP-impacted soil that was removed from the site, EAT also excavated a 200 foot stretch of sediment from the bottom of Darby Creek (totaling 4,000 tons). The sediment excavation required the following:

- Installation of a PortaDam both upstream and downstream of the excavation area. Two 48” x 200’ HDPE pipes were utilized in conjunction with the PortaDam to allow Darby Creek to bypass the excavation area.

- Installation and operation of localized sumps to minimize water in the excavation area

- Stabilization of saturated soils with cement kiln dust

A portion of the Darby Creek sediment excavation was around a 48” sewer main, which ran perpendicular to Darby Creek. The sewer main was approximately 60 years old and carries approximately 14 million gallons of sewage per day. EAT injection grouted underneath and on both sides of the sewer main to stabilize the pipe during excavation.

This project also required extensive restoration, including the following:

- Construction of a boulder wall on top of bedrock by stacking ½ ton boulders.

- Restoration of the creek bed

- Installation of Coir matting

- Installation of live stakes, various trees, shrubs, plugs and specialty grass mixtures

EAT completed the project to the satisfaction of the Client and property owner.